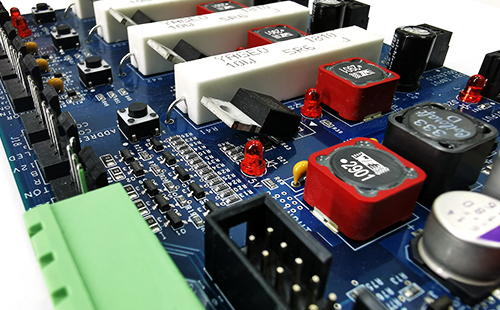

In PCB Assembly, SMT components and DIP components are the most commonly used components, and each has its own advantages and disadvantages.

The Difference Between SMT Components and DIP Components In PCBA

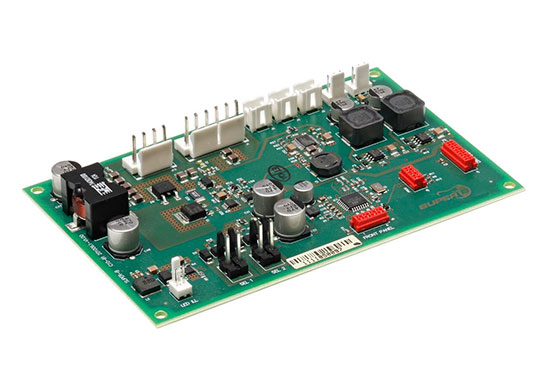

1)Advantages of choosing SMT Components

1. Reduce product volume: The volume of SMD components is only about 1/10 of that of traditional plug-in components; after general SMT Assembly, the volume of electronic products is reduced by 40% to 60%.

2. Improve production efficiency and reduce costs: SMT component is easy to automate, improve production efficiency, save materials, energy, equipment, manpower, time, etc., and reduce costs by 30% to 50%.

3. Light weight: The weight of the patch component is only 10% of the traditional plug-in component; generally, the weight of the product is reduced by 60% to 80% after using SMT.

4. High reliability and strong anti-vibration ability.

5. Good high frequency characteristics, reduce electromagnetic and radio frequency interference.

6. Low solder joint defect rate.

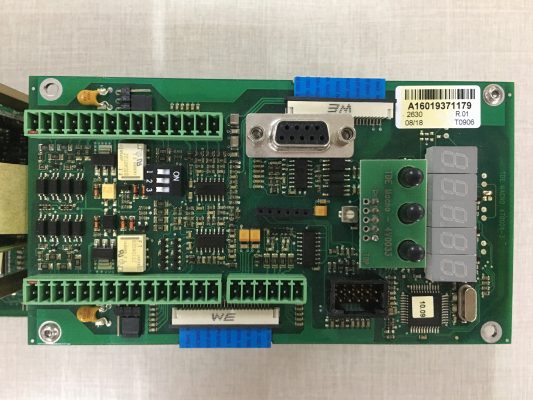

2)Advantages of using DIP Components

1. They are all power devices, which require high heat dissipation, and their performance is much higher than that of SMD components, which can keep the product’s performance stable and lasting.

2. The failure rate is low, it is easy to check, it can directly feedback the defect, and it does not need to use special equipment.

3. Better anti-bump performance, facing high-frequency, high-amplitude vibration and bumps, it can maintain the stable performance of the product better than SMD components.

PCBA Capability

1. The largest board: 310mm*410mm (SMT);

2. Maximum board thickness: 3mm;

3. Minimum board thickness: 0.5mm;

4. The smallest Chip parts: 0201 package or parts above 0.6mm*0.3mm;

5. The maximum weight of mounted parts: 150 grams;

6. Maximum part height: 25mm;

7. Maximum part size: 150mm*150mm;

8. Minimum lead part spacing: 0.3mm;

9. The smallest spherical part (BGA) spacing: 0.3mm;

10. The smallest spherical part (BGA) diameter: 0.3mm;

11. Maximum component placement accuracy (100QFP): 25um@IPC;

12. Mounting capacity: 3 to 4 million points/day.