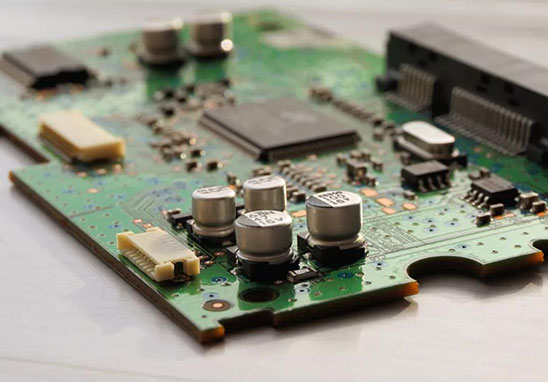

Do you know? A normal and complete PCBA production line is equipped with Solder Paste Printers, SMT Machine, Reflow Soldering Equipment, Wave Soldering Equipment, AOI Machine, and other equipments. So what matters should pay attention to during PCB Assembly?

What should pay attention to during PCB Assembly?

1. Transportation

In order to prevent PCBA damage, the following packaging should be used during transportation: anti-static turnover box is generally used for the container; the isolation material is anti-static pearl cotton. The placement distance should be greater than 10mm between the PCB board and the board, and between the PCB board and the box. The placement height must be more than 50mm away from the top surface of the turnover box to ensure that the turnover box does not press on the power supply, especially the power supply of the cable.

2. PCBA Board Cleaning Requirements

The board surface should be clean and tidy, free of tin beads, component pins, and stains. Especially at the solder joints on the plug-in surface, there should not be any dirt left by soldering. When washing the board, you must pay attention to the following components: wires, connecting terminals, relays, switches, polyester capacitors and other corrosive components, and the relay is strictly prohibited from cleaning with ultrasonic.

3. Board Edge

After all components are installed, they are not allowed to extend beyond the edge of the PCB board.

4. PCBA Board Through Reflow Oven

Due to he pins of the plug-in components are scoured by the tin flow, some plug-in components will be tilted after the reflow oven is soldered, causing the component to exceed the silk screen frame. Therefore, the repair soldering personnel after the tin furnace are required to make appropriate corrections.

1. The horizontal floating high-power resistor can be righted once, and the righting angle is not limited.

2. Horizontal floating diodes (such as DO-201AD packaged diodes) or other components with a component pin diameter greater than 1.2mm can be centered once, and the centering angle is less than 45°.

3. Vertical resistors, vertical diodes, ceramic capacitors, vertical fuses, varistors, thermistors, semiconductors (TO-220, TO-92, TO-247 packages), the bottom of the component floats greater than 1mm It can be righted once, and the righting angle is less than 45°; if the bottom of the component floats less than 1mm, you must use a soldering iron to melt the solder joints for righting, or replace with a new device.

4. In PCB Assembly, electrolytic capacitors, manganese copper wires, inductors with skeletons or epoxy board bases, and transformers are not allowed to be centered in principle. Soldering is required at a time. If there is a tilt, a soldering iron is required to melt the solder joints and then perform centering. Or replace with a new components.