In order to ensure the quality of the finished product of the PCB board production process, reliability and adaptability tests are required. The temperature resistance test of the PCB board is to prevent the PCB board from exploding, blistering, delamination and other adverse reactions at excessively high temperatures, resulting in poor product quality or direct scrapping, which is a problem that needs attention. So what is the maximum temperature resistance of the PCB board, and how to do the heat resistance test?

The temperature problem of the PCB board is related to the temperature of its raw materials, solder paste, and surface parts. Usually, the PCB board can withstand a maximum temperature of 300 degrees for 5-10 seconds; The temperature is about 260 for lead-free wave soldering, and about 240 for lead-free wave soldering.

PCB Board Heat Resistance Test

1. First prepare the PCB board production board and tin furnace.

Sampling 10*10cm substrate (or laminated board, finished board) 5pcs; “(Copper-containing substrate without foaming and delamination).

Substrate: 10cycle or more; Laminate: LOW CTE 150 10cycle or more; HTg material 10cycle or more; Normal material 5cycle or more.

Finished board: LOW CTE 150 above 5cycle; HTg material above 5cycle; Normal material above 3cycle.

2. Set the temperature of the tin furnace to 288+/-5 degrees, and use a contact thermometer to measure and correct it.

3. First dip the flux with a soft brush and apply it to the surface of the board, and then use the crucible tongs to take the test board and immerse it in the tin furnace. After 10 seconds, take it out and cool it to room temperature.

4. If there is a problem of bubbling and bursting of the board visually, stop the tin immersion and analyze the initiation point f/m immediately. If there is no problem, continue to cycle until the board bursts, with 20 times as the end point.

5. The blistering area need to be sliced and analyzed to understand the source of the detonation point and take pictures.

The PCB board will have some bad problems at overheating temperature. Therefore, it is necessary to understand the temperature resistance of the PCB board of different materials in detail, and not exceed its maximum limit temperature, so as to avoid the scrap of the PCB board and increase the cost.

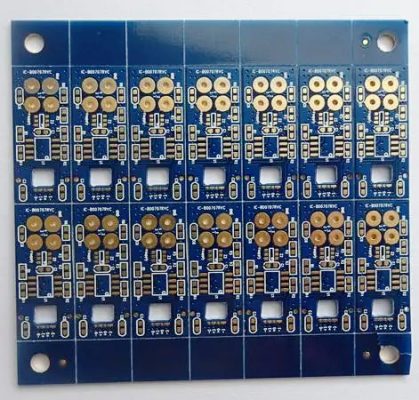

Grande PCB Board Production Capacity

Energy production 2 to 14 layers, 14-22 layers can be produced by proofing.

Minimum trace width/spacing: 3mil/3mil BGA spacing: 0.20MM

Minimum aperture of finished product: 0.1mm Size: 610mmX1200mm

Ink: Japan Tamura, Taiyo, Futoken;

FR4: Shengyi, Kingboard, Haigang, Hongren, Guoji, Hazens, South Asia,

(Shengyi S1130/S1141/S1170), Tg130℃/ Tg170℃ Tg180℃ and other high TG plates)

High frequency board: Rogers (Rogers), Taconic, ARLLON;

Surface technology: Spray tin, lead-free spray tin, ENIG, full board gold plating, plug gold plating, full board thick gold, chemical immersion tin (silver), anti-oxidation (OSP) blue glue, carbon oil