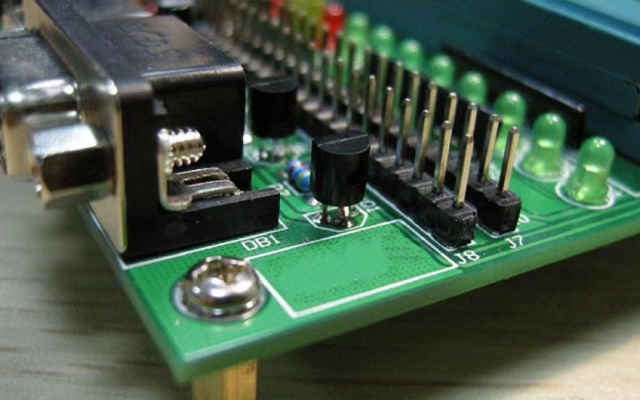

If you want to make a PCB board, then you need to go through a number of tedious and complicated processes. However, if there are some operational mistakes in the production process of the PCB board, and which will lead to quality problems in the finished board, which will not meet the product requirements. Among of them, the common PCB trace disconnection problem will affect the realization of the PCB function.

What Is The Cause of the PCB Trace Disconnection?

1. Sticking Film Process: If the film is not firmly attached, and bubbles appear. If the film is wet, there will be garbage pollution.

2. Exposure Process: Problems caused by scratches or garbage on the negative, including problems with the exposure machine, partial insufficient exposure, etc.

3. Development Process: The development is blurry and unclear.

4. Etching Process:The nozzle pressure is too large and the etching time is too long.

5. Electroplating Problem: When electroplating, the electroplating is uneven or the surface has adsorption force.

6. Improper Operation: During the production process of the circuit board, the circuit board is scratched and broken due to improper operation.

What is the cause of the PCB trace disconnection? First of all, look at the form of the disconnection. By analyzing the form of the disconnection, find out which process is the problem that caused the disconnection of the PCB board. Then investigate and analyze the cause.

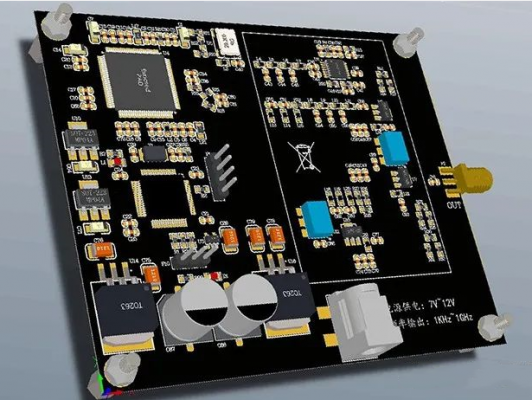

Grande Advantages In PCB Manufacturing

Mass Production 2 to 14 layers; Sample Production: 14-22 layers.

Minimum Trace Width/Spacing: 3mil/3mil BGA spacing: 0.20MM

Minimum Aperture of Finished Product: 0.1mm Size: 610mmX1200mm

Ink: Japan Tamura, Taiyo, Futoken;

FR4: Shengyi, Kingboard, Haigang, Hongren, Guoji, Hazens, South Asia,

(Shengyi S1130/S1141/S1170), Tg130℃/ Tg170℃ Tg180℃ and other high TG plates)

High frequency board: Rogers (Rogers), Taconic, ARLLON;

Surface Technology: Spray tin, lead-free spray tin, immersion gold, full board gold plating, plug gold plating, full board thick gold, chemical immersion tin (silver), anti-oxidation (OSP) blue glue, carbon oil

Advantages Grande Circuit Board Assembly

1)Strength Guarantee

▪ SMT factory: With imported SMT machines and multiple optical inspection equipment, which is able to produce 4 million points per day. Each process is equipped with QC personnel who will keep an eye on product quality.

▪ DIP production line: Two wave soldering machines and more than 10 employees who have worked for over three years. That’ s to say, these workers are highly skilled and can weld various SMT & DIP components.

2)Quality Assurance With High Cost Performance

▪ High-end equipment can paste precision special-shaped parts, BGA, QFN, 0201 package. It can also be soldered prototype pcba via SMT machine and placing bulk materials by hand.

▪ Both samples, small and large batches can be produced. And there is no SMT Machine starting cost.

3)Rich Electronic Products SMT Soldering Experience With Stable Delivery

▪ Accumulated services to thousands of electronics companies, involving SMT soldering services for various types of automotive equipment and industrial control motherboards. Furthermore, PCBA Products are often exported to Europe and the United States, and the quality is able to be affirmed by new and regular customers.

4)Strong Maintenance Ability & Reliable After-Sales Service

▪ The maintenance engineers have sophisticated experience so that those defective boards caused by all kinds of smt soldering can be repaired. Meanwhile, ensuring the connectivity rate of each circuit board also make sense.

▪Order problems feedback will get response, solution and solved as soon as possible.