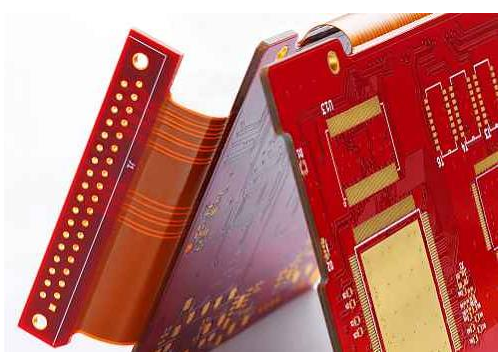

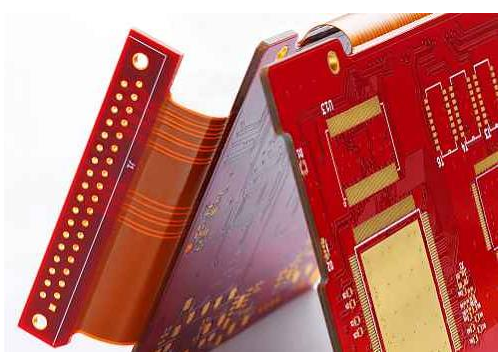

What are PCB stiffeners?

PCB stiffeners play an important role in providing mechanical support for PCB. They play an important role for flexible circuit board PCBA processing when stiffness is required in certain areas.

PCB stiffeners are especially needed when components are placed in flexible areas where the weight of these components can put pressure on the flexible material. They can also be used to create a rigid PCB surface to place components and solder in SMT processing. In addition, connectors that require multiple insertions require PCB stiffeners to reduce the stress on the PCB pads. Let’s look at the uses of PCB stiffeners in more detail.

1、Various uses of PCB stiffeners?

Simply put, PCB stiffeners are used where a certain area of the circuit needs to be hardened. Some common reasons for using stiffeners in PCBA processing:

1. Circuit board support area with SMT or SMD component PTH components.

2. Maintain a reasonable thickness of the flex circuit.

3. Support PCB connector.

4. Make sure the board is better handled.

5. Make sure the board area is stable.

6. Helps route and reserve the array.

7. Helps to relieve stress and effectively dissipate heat.

2、 Broadly speaking, flexible PCB (FPC) stiffeners are required to fall into the following usage categories:

1. Rigid component/connector area

2. ZIF (Zero Insertion Force) Thickness Requirements

3. Local Bending Constraints

3. Component/connector stiffeners

They essentially create a rigid area connected to the area. They also protect the solder joints to ensure flexibility in the component area without bending.

4. ZIF stiffeners

They ensure increased thickness at the contact fingers to meet specific ZIF connector specifications.

5. Local Bending Constraints

They confine the bending area to a specific location in the flexible design.

About Grande

Grande PCBA specializes in providing overall PCBA electronic manufacturing services, including upstream electronic components procurement to PCB production and processing, SMT placement, DIP plug-in, PCBA testing, finished product assembly and other one-stop services.

The company gives full play to its competitive advantages in scale procurement and quality control, and has signed long-term cooperation agreements with many domestic and global electronic component manufacturers to ensure the quality and stable supply of raw material sources and transfer the benefits to customers.

Long-term procurement advantages in IC, resistors, capacitors, inductors, diodes and other components can greatly save customers’ inventory costs, improve production turnaround efficiency and save time. At present, we provide PCBA processing service for customers in USA, UK, Japan, Russia, France, Canada, Australia, Romania, Switzerland and other countries and regions.

We provide PCBA processing services, starting from PCB board fabrication, our own PCB manufacturer (with extremely strict TS16949 certification for the automotive industry), focusing on the quality of the board and PCBA quality control system.

Due to decades of experience in procurement of electronic components, we maintain long term cooperation with large brands to ensure the original packaging of components and procurement channels. In the encapsulation process of components, we choose Senju and Loctite solder paste to ensure the reliability of the soldering, with automatic printing machine, Panasonic high-speed placement machine, upper and lower eight temperature zone reflow soldering, AOI automatic optical detector, etc., which can effectively ensure the reliability and quality of the electronic packaging process.

In addition, the perfect management process of IPC, IPQC, OQA, etc., with clear job responsibilities and strict implementation of IPC electronic assembly acceptance standards. Regarding PCBA testing, we have professional engineers to perform 100% batch testing using various test stands, including pathway, noise, amplitude, signal, temperature, humidity, drop or execute customer’s detailed test program. All efforts aim to be a fine PCBA processing manufacturer.