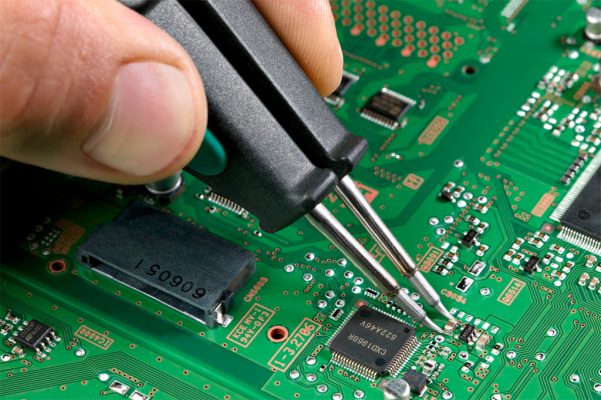

The introduction of SMT lead-free Technique has always been a challenge for PCB Assembly for the first time, because if require PCBA repair, it will face more challenges. Performing PCBA repair in a lead-free environment will have higher cost, quality details, time and repeatability issues, and all these issues need pay more attention to.

SMT Lead-Free Technique Requirements:

1. Train operators for lead-free assembly, maintenance and inspection, and evaluate time and cost.

2. Lead-free solder materials are more expensive than traditional solders, such as lead-free wires, welding rods and core solders.

3. The processing temperature (about 30-35°C) of lead-free assembly requires high precision.

4. The lead-free process also requires research and planning of the smt factory to establish the correct PCBA repair process.

Grande believes that the best practice for PCBA repair is to first train and instruct technicians, and develop configuration files based on the characteristics of lead-free processes. Defined rework standards. Regardless of whether standard solder or lead-free solder is required, the process starts in the same way. The steps required are as follows:

1. Define and execute precise thermal profile

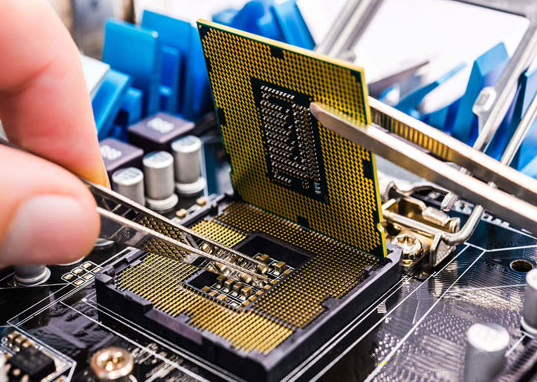

2. The failed component must remove

3. Clean up all rust or solder residues on the board and prepare new components

4. Replace components with new solder, flux and reflow soldering

5. Thoroughly check the repair after finished

In a lead-free environment, accurate and reliable rework is more difficult because the PCBA and the components closest to the parts that need to be repaired must withstand multiple high temperature cycles. In order to protect the stability of the circuit board, the preheating temperature should be set not higher than the glass transition temperature of the PCB material.

The next steps involved in the repair process depend on whether there is a lead-free requirement. The difference between standard and lead-free brings many challenges that can only be solved by introducing new or changed processes, including stricter and more precise thermal profiles and extremely high precision throughout the PCBA repair process. This will avoid many costly problems caused by different heat distributions.