In the process of SMT Assembly, we will often come into contact with three kinds of pastes, namely solder paste, tin paste and flux paste. The names of the three pastes are similar, but from a professional point of view, they will be quite different.

The Difference & Connection of Solder Paste, Tin Paste & Flux In SMT Assembly

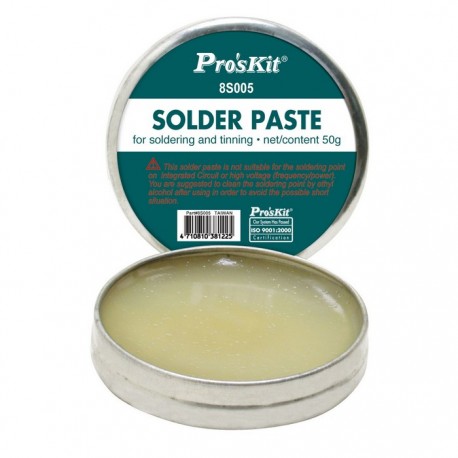

In fact, from a certain point of view, solder paste, tin paste and flux are the same thing, that is, solder paste, but the name is different in Chinese. tBut there are many people who regard solder paste and flux as a product. As a matter of fact, solder paste is paste, whose main component is a paste-like object composed of metal alloy powder.

However, the flux is different, which mainly plays the role of a flux, and its main components are rosin, active agent and solvent. A certain proportion of flux paste will be added to the solder paste during the production process.

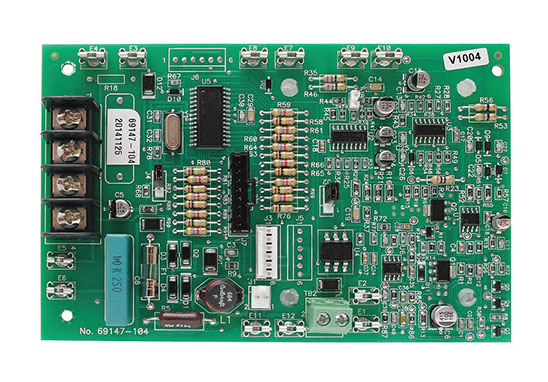

The role of tin paste: Alloy powder; To complete the mechanical and electrical connection between electronic components and circuit boards.

The role of solder paste:

1. The carrier of tin powder particles provides suitable rheology and wet strength, which is conducive to the transfer of heat to the soldering area, reduces the surface tension of the solder, and prevents the re-oxidation of the solder and the welding surface during welding.

2. Remove the oxide layer of the soldering surface and tin powder particles, and form a protective layer and a safe residue layer on the surface of the soldering point.

3. The proportion of flux paste can be arbitrarily mixed with various solder powders (tin, silver, copper, bismuth, lead), and can also be mixed with high, medium and low temperature solder powders (100-260) ℃. After being formulated into solder paste, it has the advantages of good solderability, continuous printing and less residue.

To sum up, solder paste, tin paste, and flux actually refer to two products – paste and flux. It is also very simple to distinguish these three. From the appearance color, you can distinguish between the solder paste and tin paste. The solder paste is yellowish, but the tin paste will be gray or black. This is because the component of tin powder is added to the solder paste, and the solder paste is only a pure paste to play a certain role in soldering.

The above is the introduction of the difference and connection of solder paste, tin paste and flux in SMT Assembly.

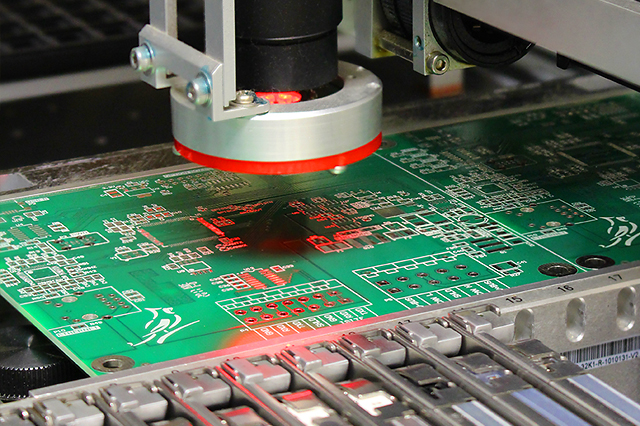

PCBA Capability

1. Maximum Board: 310mm*410mm(SMT);

2. Maximum Board Thickness: 3mm;

3. Minimum Board Thickness: 0.5mm;

4. Minimum SMD Component: 0201 package or components above 0.6mm*0.3mm;

5. Maximum Weight of Mounted Component: 150 grams;

6. Maximum Component Height: 25mm;

7. Maximum Component Size: 150mm*150mm;

8. Minimum Pin Spacing: 0.3mm;

9. Minimum Spherical Component (BGA) Spacing: 0.3mm;

10. Minimum Spherical Component (BGA) Ball Diameter: 0.3mm;

11. Maximum Component Placement Accuracy (100QFP): 25um@IPC;

12. SMD Capacity: 3-4 million points/day.

Advantages of PCB Assembly In Grande

1. Highly Professional: Grande focuses on PCBA Samples, small and medium batches; For 2 Layer Simple Sample PCBA, Grande promises to deliver within 3-7 working days after the materials are confirmed to be OK.

2. Professional Equipment: Advanced equipment tailored for sample and small and medium batch production, and can be pasted with 0201, BGA spacing 0.3MM, QFN, CSP, CON and other components.

3. Professional Technology: 100% of technical backbones have more than 5 years of work experience, and 85% of front-line operators have more than 3 years of work experience.

4. Grande implements the 5S and 6σ concepts in daily operations, and it is expected that the shipment will be checked at least 7 times.

5. Grande promises that the soldering pass rate is above 99%. If the customer finds soldering defects, the company promises to repair it free of charge.