After the PCB Assembly, we often see many residues on the surface of the PCBA. These residues not only affect the appearance of the PCBA, but most importantly, the quality of the PCBA board. Therefore, PCBA cleaning is super important. Now, let’s see the correct method of PCBA board manual cleaning.

Some small and medium-sized PCBA factories usually use the method of manual PCBA cleaning, because the manual cleaning method has lower cost and relatively high cost-effectiveness. Manual cleaning tools include cleaning cans, spray cans, brushes, IPA or VIGON EFM, gloves, deionized water, wipes, air guns and airtight bags.

The Steps of Manual PCBA Cleaning

1. Clean the circuit board in IPA or VIGON EFM, or spray IPA and EFM on the surface of the circuit board, using about 10 ml per 4 square inches.

2. Use a damp soft short-bristle brush to wipe the circuit board continuously for about 10 seconds.

3. Rinse with deionized water, approximately 10 ml per 4 square inches. Effectively removes potential contaminant residues.

4. Hold the edge of the circuit board and wipe off excess deionized water with a clean, lint-free wipe.

5. Visually inspect the cleanliness of the circuit board.

6. If necessary, use an air gun to dry the circuit board.

7. If the circuit boards or components need to be stored for a period of time before coating, please put the circuit boards or components in a sealed bag containing desiccant.

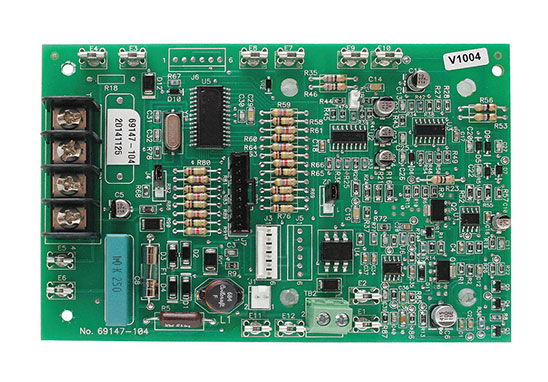

When the batch of PCB circuit boards is relatively large, the disadvantages of the manual cleaning method will appear. For example, the efficiency is relatively low and the cleaning is not comprehensive and meticulous. Many electronic components cannot be cleaned in place in the gaps, such as IC one. This type of integrated circuit has a lot of pins, and it is very close to the substrate, so the brush cannot enter it for cleaning. Therefore, manual cleaning of PCBA has gradually begun to be replaced by automatic cleaning.