In the manual soldering process of SMT Assembly, short circuit is a common defect. In order to achieve the same effect between hand placement and machine placement, the short circuit problem must be resolved. If there is a short circuit on the PCBA circuit board, it must not be used. Fortunately, there are also plenty of useful methods to solve the short circuit problem in manual soldering.

Methods of Avoiding Short Circuit In Manual Soldering

1. It is necessary to develop a good habit of manual soldering operation. Use a multimeter to check whether the key circuit is short-circuited.If an IC is manually soldering, you need to use a multimeter to measure whether the power supply and the ground are short-circuited every single time.

2. Light up the short-circuited network on the PCB diagram, find the most short-circuited place on the circuit board, and pay attention to the short-circuit inside the IC.

3. If there is a short circuit in the same batch in the SMT Assembly, you can take a board to cut the line, and then energize each part to check the short circuit part.

4. Use a short-circuit location analyzer to check.

5. If there is a BGA chip, since all the solder joints are covered by the chip and invisible, and it is a multi-layer board (more than 4 layers), it is best to separate the power supply of each chip during design, and use magnetic beads or 0 ohms. Resistor connection, so that when there is a short circuit between the power supply and the ground, the magnetic bead detection is disconnected, and it is easy to locate a certain chip.

6. Be careful when soldering small-sized surface mount capacitors, especially the power supply filter capacitors (103 or 104), which are super large in number, which can easily cause a short circuit between the power supply and the ground.

PCBA Advantages of Grande

1. Highly professional: Grande focuses on processing samples, small and medium batches, and promises to deliver within 3-5 working days after the materials are confirmed to be correct.

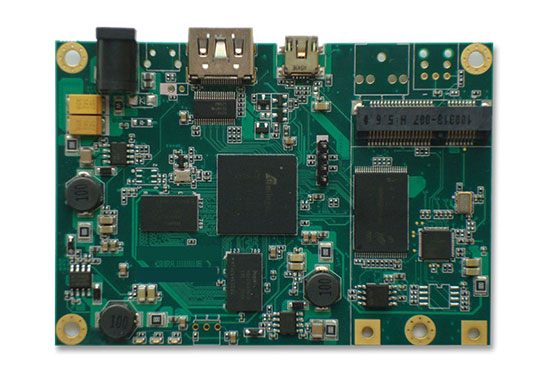

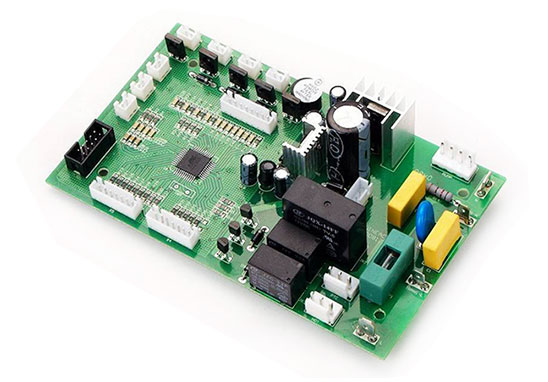

2. Professional equipment: Grande’s equipment is advanced equipment tailored for sample and small and medium batch production, and can be pasted with 0201, BGA spacing 0.3MM, QFN, CSP, CON and other components.

3. Professional Technology: 100% of technical backbones have more than 5 years of work experience, and 85% of front-line operators have more than 3 years of work experience.

4. Grande implements the 5S and 6σ concepts in daily operations, and it is expected that the shipment will be checked at least 7 times.Grande promises to pass AOI optical inspection if the quantity reaches 100PCS.

5. Grande promises that the welding pass rate is above 99%. If the customer finds welding defects, the company promises to repair it free of charge.

Grande PCB Assembly Advantages

1)Strength Guarantee

2)Quality Assurance With High Cost Performance

3)Rich Electronic Products SMT Soldering Experience With Stable Delivery

4)Strong Maintenance Ability & Reliable After-Sales Service