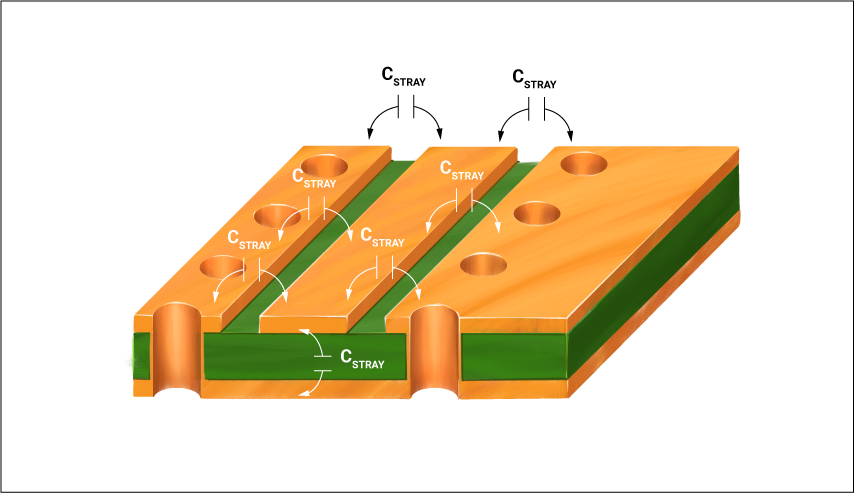

When referring to electronic circuits on the PCBA, a term often used is stray capacitance. Stray capacitance can exist between conductors on PCBs, prefabricated circuit boards for passive components, PCBA, between boards with mounted components, and between SMD component kits in component packages (especially ICs). Stray capacitance is one of the physical properties inherent in electronic circuits and circuit boards. So how to reduce the impact of PCB stray capacitance?

Reduce PCB Stray Capacitance By PCB Design

1. Remove the inner ground plane

Since ground planes can increase capacitance with adjacent conductors due to their proximity, it helps to remove inner ground planes to increase the distance, which will minimize capacitive effects. This must be weighed against the benefit of minimizing the EMI gained when the ground plane is adjacent to the signal plane.

2. Use the Faraday Shield

A Faraday shield is a ground trace or plane that is placed between two traces, the PCB is designed to minimize capacitive effects between them, and like other shielding structures, it effectively reduces stray capacitance.

3. Increase the space between adjacent traces

Another effective mitigation technique is to increase the spacing between adjacent traces. This is a quite good method to apply as capacitance decreases with distance.

4. Minimize the use of vias

Through holes are a key element in making compact, complex PCBs possible. However, overuse may increase parasitic capacitance problems. Such as stray capacitance. This PTH coupling can be reduced by PCB design eliminating annular rings around vias on unconnected layers and minimizing the number of vias from components. Such as BGA.

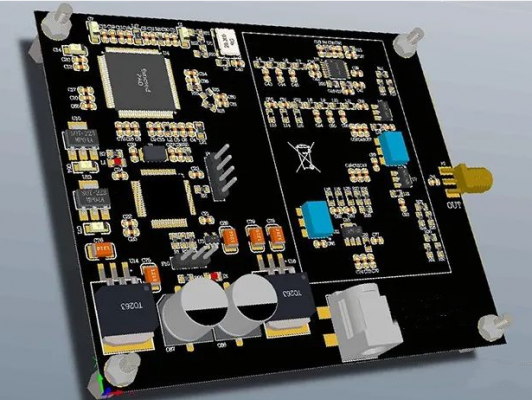

Grande Electronic Circuit Board Design Capabilities

Maximum signal design rate: 10Gbps CML differential signal

Maximum PCB design layers: 40 layers

Minimum trace width: 2.4mil

Minimum trace spacing: 2.4mil

Minimum BGA PIN spacing: 0.4mm

Minimum mechanical hole diameter: 6mil

Minimum laser drilling diameter: 4mil

Maximum number of PINs: 63000+

Maximum number of components: 3600

Maximum number of BGAs: 48+

Grande PCB Assembly Advantages

1)Strength Guarantee

2)Quality Assurance With High Cost Performance

3)Rich Electronic Products SMT Soldering Experience With Stable Delivery

4)Strong Maintenance Ability & Reliable After-Sales Service