The surface finish of the Printed Circuit Board (PCB) usually has three colors: Gold, Silver, Light Red. Simple speaking, gold is the most expensive, silver is cheaper, and light red is the cheapest.

How To Identify PCB Surface Finish By Color?

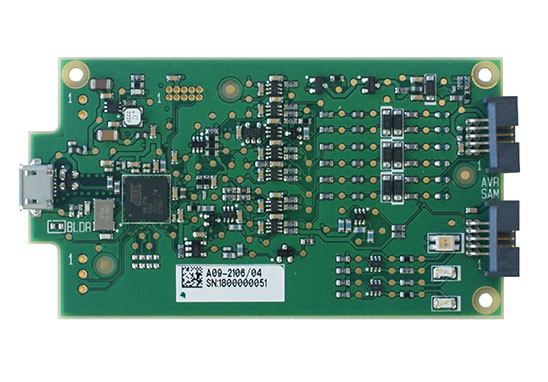

1. Gold

Gold is real gold, even if only a thin layer, it accounts for nearly 10% of the cost of the circuit board. The purpose of using gold is to facilitate soldering and to prevent corrosion. The gold-plated layer is widely used in the component pads, gold fingers, connector shrapnel and other positions of the circuit board.

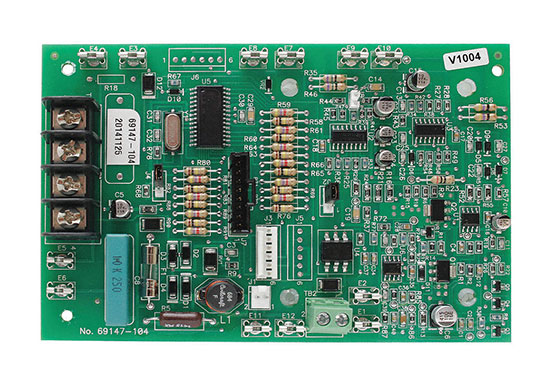

2. Silver

The silver circuit board is called spray tin board. Spray a layer of tin on the outer layer of the copper circuit to help soldering. The tin-sprayed board has no effect on the components that have been soldered, but for the pads exposed to the air for a long time, the reliability is not enough, and the long-term use is easy to oxidize and corrode, resulting in poor contact.

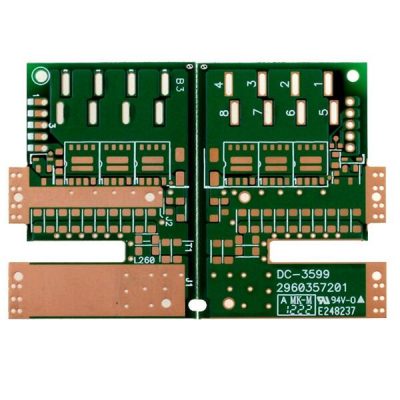

3. Light Red

OSP, organic flux film, is organic rather than metal, and the price is cheaper than the tin spray process. The only function is to ensure that the inner copper foil will not be oxidized before soldering. When the soldering heats up, the film volatilizes. OSP can solder copper wires and components together when soldering, but it is not resistant to corrosion. An OSP circuit board, exposed to the air for ten days, then which cannot solder components anymore.

Grande PCB Manufacturing Advantages

Mass production 2 to 14 layers, 14-22 layers can be produced by prototype.

Minimum Trace Width/Spacing: 3mil/3mil BGA spacing: 0.20MM

Minimum Aperture of Finished Product: 0.1mm Size: 610mmX1200mm

Ink: Japan Tamura, Taiyo, Futoken;

FR4: Shengyi, Kingboard, Haigang, Hongren, Guoji, Hazens, South Asia,

(Shengyi S1130/S1141/S1170), Tg130℃/ Tg170℃ Tg180℃ and other high TG plates)

High Frequency Board: Rogers (Rogers), Taconic, ARLLON;

Surface Technology: Spray tin, lead-free spray tin, immersion gold, full board gold plating, plug gold plating, full board thick gold, chemical immersion tin (silver), anti-oxidation (OSP) blue glue, carbon oil

Advantages Grande Circuit Board Assembly

1)Strength Guarantee

2)Quality Assurance With High Cost Performance

3)Rich Electronic Products SMT Soldering Experience With Stable Delivery

4)Strong Maintenance Ability & Reliable After-Sales Service