With the rapid development of high-tech industries such as mobile phones, electronics devices, communication industries, and autonomous driving, it has largely driven the continuous expansion and rapid growth of the Printed Circuit Board (PCB) industry. The requirements for materials, colors, reliability are also getting higher and higher.

It is also due to the fierce market price competition and the rising trend of circuit board material costs. In order to enhance the core competitiveness of the industry, more and more manufacturers choose to try to monopolize the market at low prices. However, behind these ultra-low prices, they are often obtained by reducing material costs and process manufacturing costs. In this case, the quality of the circuit board itself cannot be achieved, so the circuit board is usually prone to cracks and scratches. The comprehensive factors such as precision and performance are not up to the standard, which seriously affects the reliability of the circuit board. For the various circuit board manufacturers on the market, then How to distinguish the quality of PCB from appearance?

Method of distinguish the quality of PCB from appearance

Under normal circumstances, the circuit board can be analyzed and judged through several aspects of its appearance;

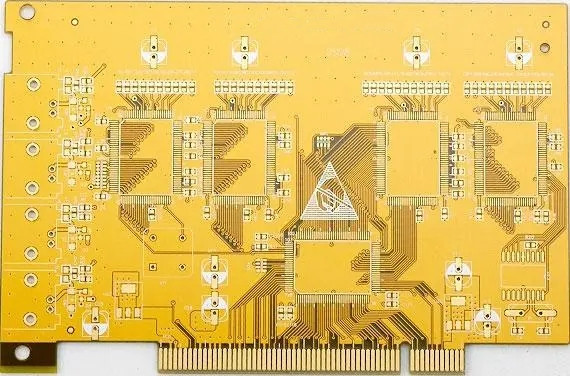

1. Light and color

The external PCB circuit board is covered with solder mask, and the circuit board can play the role of insulation. If the color of the board is not bright and there is less solder mask, the insulation board itself is not good.

2. Standard rules for PCB size and thickness

The thickness of the circuit board is different from that of the standard circuit board, and customers are able to measure and check in the light of the thickness and specifications of their own products.

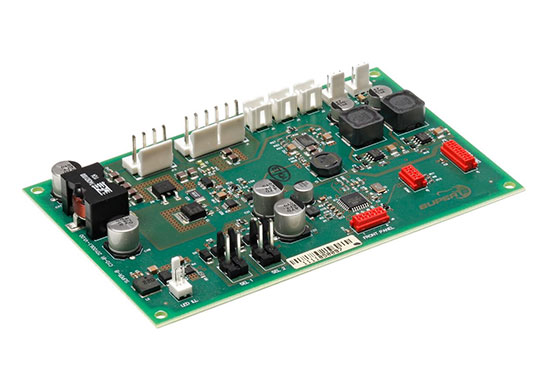

3. The appearance of the soldering seam of the PCB

Because the circuit board will be soldered a great number of components when do PCB Assembly; If the soldering is not good, the components are easy to fall off the circuit board, which will seriously affect the solderinh quality of the circuit board.

Grande’s PCB board advantages

Energy production 2 to 14 layers, 14-22 layers can be produced by prototype.

Minimum trace width/spacing: 3mil/3mil BGA spacing: 0.20MM

Minimum aperture of finished product: 0.1mm Size: 610mmX1200mm

Solder Mask: Japan Tamura, Taiyo, Futoken;

FR4: Shengyi, Kingboard, Haigang, Hongren, Guoji, Hazens, South Asia,

(Shengyi S1130/S1141/S1170), Tg130℃/ Tg170℃ Tg180℃ and other high TG plates)

High frequency board: Rogers (Rogers), Taconic, ARLLON;

Surface technology: spray tin, lead-free spray tin, immersion gold, full board gold plating, plug gold plating, full board thick gold, chemical immersion tin (silver), anti-oxidation (OSP) blue glue, carbon oil