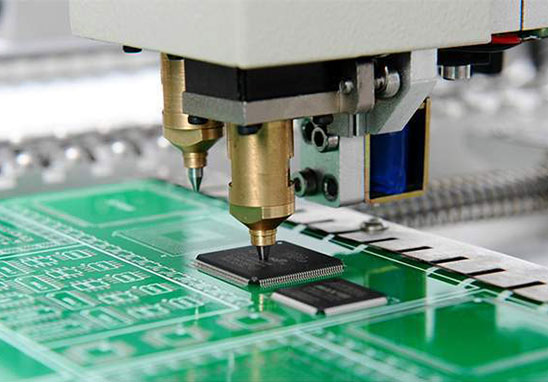

How to make sure the SMT Assembly is good and fast? In fact, both human factor and the material factor are vital. The human part is the coordination of engineers, technicians and operators; While the material factor is the SMT placement machine, and which must take into account the requirements of the production line for the placement machine. So how to choose a qualified SMT Placement Machine? In other words, what are the conditions for the SMT placement machine to meet the requirements of the production line?

SMT Placement Machine Meets The Requirements of The Production Line

1. Component Placement Accuracy

High-precision placement plays a decisive role in controlling the accuracy of components, PCB circuit boards and z-axis control, avoiding damage to components and PCB circuit boards as well as improving production efficiency.

2. Appropriate Pressure

The pressure of SMT Assembly is quite critical to the quality of SMD Components. If the pressure is too low, the solder ends or pins of small components will float on the solder paste, causing the solder paste to not fit the components, or the component and pad to shift through the automatic production line or reflow soldering; If the pressure is too high, it will squeeze solder paste, forming solder paste adhesion and damaging the component structure.

3. SMT Speed

Various SMT placement machines need to be adjusted to the corresponding settings due to different parameters. If it is not adjusted in time, which may lead to poor component placement function.

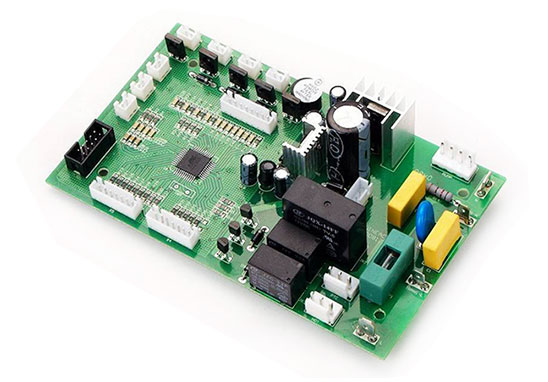

Grande SMT Assembly Capability

1. Maximum Board: 310mm*410mm(SMT);

2. Maximum Board Thickness: 3mm;

3. Minimum Board Thickness: 0.5mm;

4. Minimum Chip Components: 0201 package or parts above 0.6mm*0.3mm;

5. Maximum Weight of Mounted Components: 150 grams;

6. Maximum Component Height: 25mm;

7. Maximum Component Size: 150mm*150mm;

8. Minimum Pin Spacing: 0.3mm;

9. Minimum Spherical Component (BGA) Spacing: 0.3mm;

10. Minimum Spherical Component (BGA) Ball Diameter: 0.3mm;

11. Maximum Components Placement Accuracy (100QFP): 25um@IPC;

12. SMD Capacity: 3-4 million points/day.

Grande PCB Assembly Advantages

1)Strength Guarantee

2)Quality Assurance With High Cost Performance

3)Rich Electronic Products SMT Soldering Experience With Stable Delivery

4)Strong Maintenance Ability & Reliable After-Sales Service