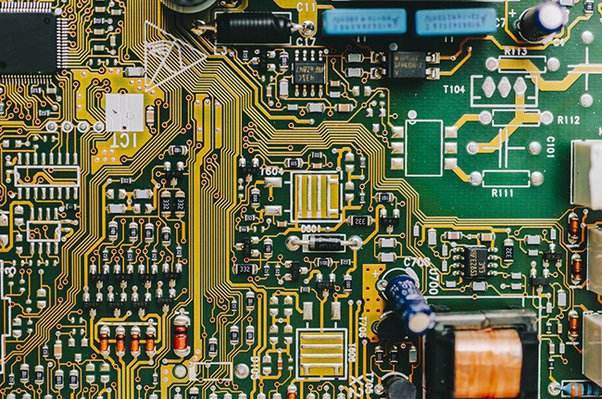

Many friends hope to receive PCBA Quotation immediately after they provide Gerber + BOM Information. Under normal circumstances, how long does it take for a complete PCBA Quotation? Which aspects of PCBA Manufacturing should be included in the calculation? Everyone knows that PCBA is a general term for Printed Circuit Board Assembly, which includes PCB Prototype, Component Procurement, SMT & DIP Assembly. Therefore, the PCBA Quotation is composed of these mentioned three parts.

PCBA Quote Calculation Method

1. PCB Cost

The board-making materials and the board-making instruction documents required for quotation in this step. If there is no lack of information, sort out the information neatly. If there are some special processes, you need to recalculate the cost, plus other additional cost calculations, and you can have a complete quotation on the same day, if there is more In other cases, the time may exceed this time.

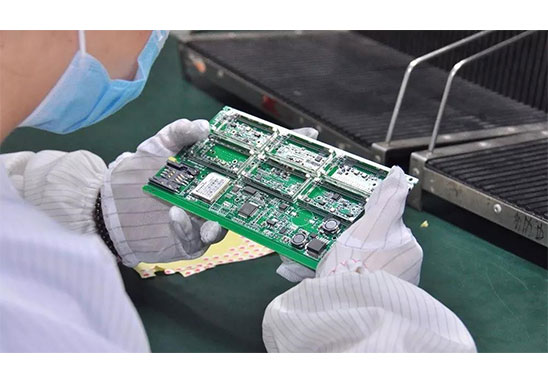

2. Assembly Cost

The main cost of this part is the calculation of Assembly fees. Generally, SMT + DIP Assembly is billed according to each soldering point. For example, some relatively small components are based on one component per point, and some are based on each foot. Generally, the components are not less than two feet. Thus, the usual unit price based on one component and one point will be higher than that of components based on one foot. So when calculating, do not just look at the unit price of the point, but concern the overall calculation and see which form It will be more cost-effective. The evaluation of this part is not too long.

3. Components cost

Components are divided into two categories, conventional resistors and capacitors also have some special components. The price of these components is relatively transparent in the market, and it is relatively easy to evaluate the price. The price evaluation of some other special BGA and IC chips will be more troublesome, because many of these components will be affected by the international embargo or strict approval process, long customs clearance time and price instability. The price of this kind of components fluctuates greatly, so the quotation takes the longest time, at least about three to four days.

Through the above simple explanation, we can understand that it takes a few days for the entire process of PCBA’s latest quotation to go down, and also the time for holidays must be excluded. Another situation is that the company itself can greatly shorten the quotation time if it reserves materials. In the three major quotation modules, the quotation of PCB boards and Assembly part is relatively fast. Only when quotations for some special components are encountered, the quotation time will be relatively long. The second is that some companies have relatively large orders and need to queue up for quotations, which also takes some time.

How to calculate the cost of PCBA for electronic products?

The hardware of electronic products is mainly composed of the price of Printed Circuit Boards, Components and Assembly, which is the cost of PCBA, Pinted Circuit Board Assembly. Let’s answer in detail about the calculation of the prices of these 3 parts:

1.PCB Cost: According to the requirements of PCB process parameters, calculate the PCB price per square meter under this parameter, and then calculate how many square meters of PCB you need to use for your product;

2.Components Cost: First open the schematic, export the corresponding BOM, group the same components into one category, and count the number of components in each category. Then according to the BOM to count the number of various components for quotation;

3.Assembly Cost: The SMT +DIP Assembly is calculated by points, so the pin statistics of the components are calculated. The unit price of different types of pins is different. After the points are calculated, the start-up fee and the stencil fee must be added, etc.

The above is an brief introduction on how to calculate the price of PCBA. Hope it can help you to some degree. BTW, If you have circuit board proofing and PCBA processing needs, please contact Grande Electronics.