After electronic product manufacturers hand over the SMT Prototype Project to PCBA manufacturers, which does not mean that they have nothing to do. On the contrary, in order to ensure that there is no problem with the product and will not affect the performance of the electronic product, the electronic manufacturer must learn to appraise the qualified standard of PCBA Prototype, so as to avoid receiving defective boards.

So, how can we judge if PCBA prototype is qualified? Grande will briefly introduceit from two aspects.

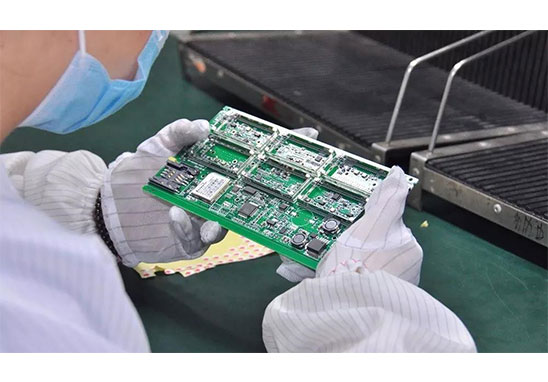

1) CheckTheAppearance of PCBA board Solder Joints

A good quality PCBA board must have a clean, smooth surface with metallic luster on the solder joints. If dirt or residue appears, which may have a certain impact on electronic products, such as easy leakage and frequent short circuits. This is a problem that often occurred in the early stage of mobile phone electronic products, and later, with the emergence of SMT Assembly technology, this phenomenon has slowly disappeared. However, if the company does not know it, such a problem may also arise.

In addition, to judge whether the PCBA board is qualified, it depends on whether there are burrs, gaps and tin drag on the surface. If yes, it will definitely affect the beauty of the SMT Assembly Prototype, and it will also bring other hazards, especially in the high voltage. During construction, tip discharge may occur, causing damage to electronic products.

The surface of the PCBA board solder joints must also be guaranteed to be free of abnormalities, otherwise it is easy to cause false soldering, false soldering, and unreliable SMT Assembly Prototype. This is well known by seasoned masters.

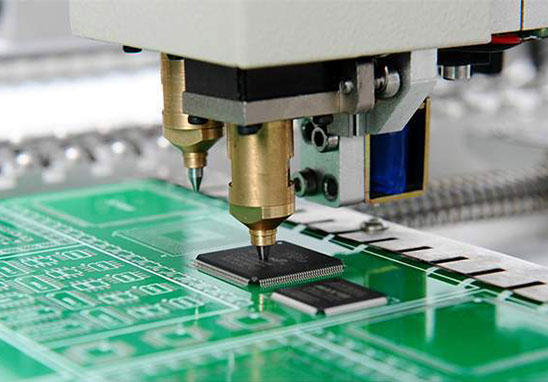

2) TestThe Reliability Of The Electrical Connection Of PCBA Board

When the surface of the component forms a virtual solder or a small amount of alloy layer, it is difficult to find this situation in the test or initial work, but as the use time increases, the contact layer is completely oxidized, it is easy to appear Desoldering, circuit breaks and turns on, not working, etc. At this time, visually inspecting the appearance of the circuit board, the circuit is connected, but it cannot work normally.

This is a very troublesome problem in SMT assembly ptototype, and it is also a situation that PCBA manufacturers will deal with carefully. In order to solve this problem, SMT assembly prototype will ensure reliable electrical connection during the manufacturing process, which is able to greatly reduce the occurrence of this situation.

Therefore, the above two points are the criteria for judging whether the SMT assembly prototype is qualified or not, just for your reference. In fact, many people are reluctant to hand over SMT assembly ptototype to other manufacturers. They feel that they can do it by themselves. Finding outsiders to do it will only increase the cost. But do you know? Really qualified SMT assembly prototype products require not only technology, but also inspection, especially testing equipment, which must be kept up. The latter is very expensive, and it is difficult for ordinary small and medium electronic companies to afford it.

Moreover, handing SMT assembly prototype to professional manufacturers not only save time, guarantee product quality, but also improve work efficiency. Although there is a need to pay, the reliability of later electronic products is guaranteed, and the company’s development is more smoothly. Therefore, instead of spending hard work in an industry you are not familiar with, it is better to contract directly to a professional SMT chip processing manufacturer, which is more reliable and safer.