At present, FPC basically includes four types: Single-sided FPC, Double-sided FPC, Multilayer FPC and Rigid-flex FPC;

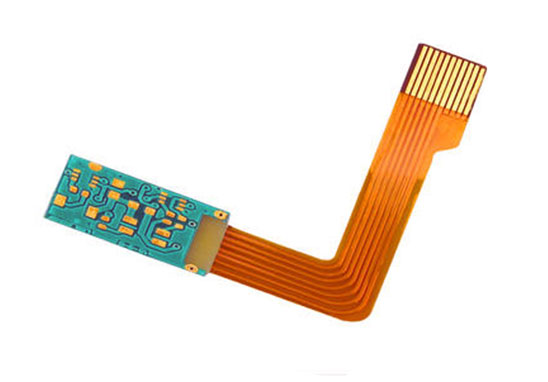

Single-sided FPC

Single-sided FPC is the lowest cost printed circuit board that do not require high electrical performance. For single-sided wiring, a single-sided flexible circuit board should be used. It has a layer of chemically etched conductive patterns, and the conductive pattern layer on the surface of the flexible insulating substrate is a rolled copper foil. The insulating substrate can be polyimide, polyethylene terephthalate, aramid cellulose ester and polyvinyl chloride.

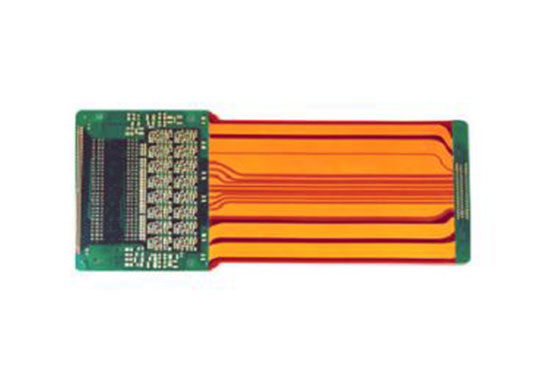

Double-sided FPC

The double-sided FPC is a conductive pattern made by etching on both sides of the insulating base film. The metallized hole connects the patterns on both sides of the insulating material to form a conductive path to meet the design and use function of flexibility. The cover film can protect single and double-sided traces and indicate where the components are placed.

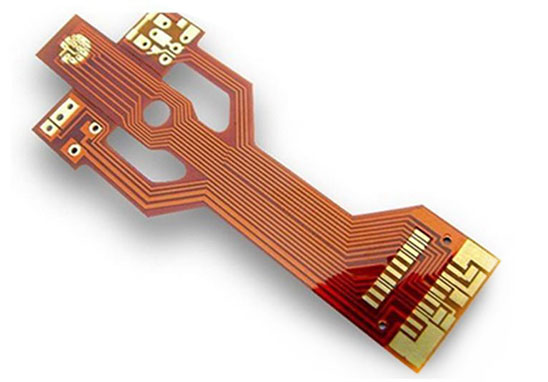

Multilayer FPC

Multi-layer FPC is to laminate 3 or more layers of single-sided or double-sided FPC flexible circuit boards together, and form metallized holes by drilling and electroplating to form conductive paths between different layers. In this way, there is no need to use a complicated welding process. Multilayer circuits have huge functional differences in terms of higher reliability, better thermal conductivity and more convenient assembly performance. When designing the layout, the mutual influence of assembly size, number of layers and flexibility should be considered.

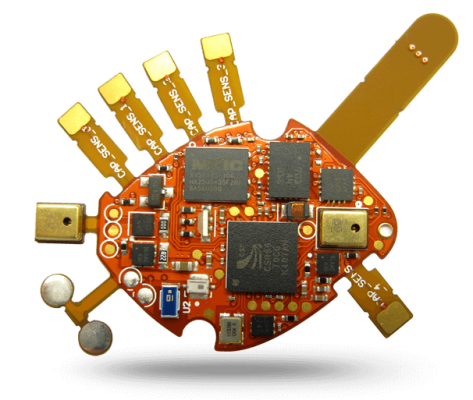

Rigid-flex FPC

The traditional rigid-flex circuit board is composed of rigid and flexible substrates selectively laminated together. The structure is compact, and the metallization hole L forms a conductive connection. If there are components on the front and back of a printed circuit board, a rigid flexible circuit board is a good choice. But if all the components are on one side, it will be more economical to choose a double-sided flexible circuit board and laminate a layer of FR4 reinforced material on its back.

The FPC flexible circuit board with hybrid structure is a multi-layer board, and the conductive layer is composed of different metals. An 8-layer board uses FR-4 as the inner layer medium and polyimide as the outer layer medium. Leads extend from three different directions of the main board, and each lead is made of a different metal. Constantan alloy, copper and gold are used as independent leads. This kind of hybrid structure is mostly used in the low temperature conditions where the relationship between electrical signal conversion and heat conversion and the electrical performance are relatively harsh, and it is the only feasible solution. It can be evaluated by the convenience of the internal connection design and the total cost to achieve the best performance-price ratio.

Grande Flexible Circuit Board (FPC) Capability

Rigid/flexible PCB layers: 10/6;

Minimum trace width and trace spacing: 3/3mil;

Board thickness aperture ratio: 12:1;

Distance from hole to conductor: 6mil;

Impedance tolerance (Ω): 10%;

Surface treatment: HAL, ENIG, immersion tin, immersion silver, HASL, hard gold plating, soft gold, silver paste, etc.