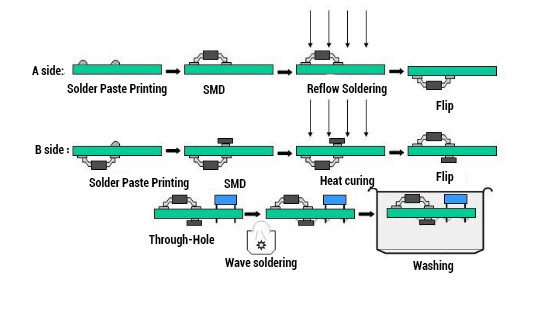

There are various stages in PCBA manufacturing process, including printing solder paste on the circuit board, component placement, soldering, inspection and testing. All these processes are necessary and need to be monitored to ensure that the highest quality PCBA products are produced.

PCBA Manufacturing Process

1)Solder Paste Printing

Before placing components to the board, you need to add solder paste on the board where solder paste is needed. These areas are usually component pads and which is achieved through a solder screen.

Solder paste is a paste formed by mixing small tin particles and flux. This can be deposited in place in one process, which is very similar to some printing processes.

Using a solder screen, place it directly on the circuit board and register it in the correct position. A runner moves through the screen, squeezing a small piece of solder paste through the hole on the screen and onto the circuit board. Since the tin screen is generated from the printed circuit board file, the tin screen has holes in the position of the tin pad, so that the solder is only deposited on the tin pad.

The amount of solder deposited must be controlled to ensure the correct amount of solder is produced in the joint.

2)SMT Assembly

In this part of the PCBA process, the solder paste-added board then enters the SMT placement process. Here, a machine loaded with reels of components selects components from reels or other dispensers and places them in the correct positions on the circuit board.

The tension of the solder paste holds the components placed on the circuit board in place. This is enough to keep them in place, provided the board is not shaken.

However, in some PCBA processes, the pick-and-place machine will add small dots of glue to fix the components on the board, which is usually only done when the board is wave soldered. Speaking of the disadvantage of this process, that is the future repair will become more difficult due to the presence of glue, although some glues are designed to degrade during the soldering process.

The position and component information required to design the pick-and-place machine comes from the design information of the printed circuit board. This greatly simplifies pick and place programming.

3)Welding

Once the components are added to the circuit board, the next stage of PCBA process, and this production process is through its welding machine. Although some boards may pass through a wave soldering machine, this process is not widely used for surface mount components these days. If wave soldering is used, no solder paste is added to the board because the solder is provided by the wave soldering machine. BTW, reflow soldering technology is more widely used than wave soldering technology.

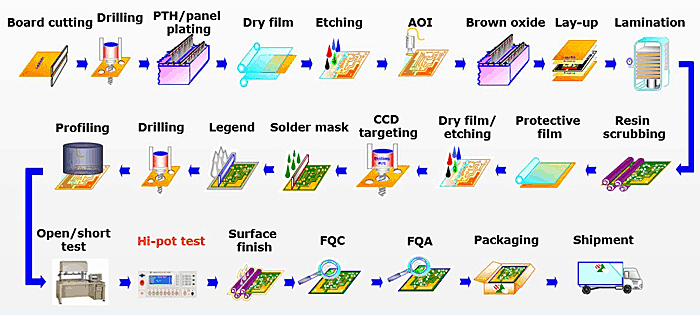

Inspection. After the circuit board passes through the soldering process, it usually needs inspect. For surface mount boards with 100 or more components, manual inspection is not an good option. On the contrary, Automatic Optical Inspection (AOI) is a more feasible & reliable solution. Existing machines are able to inspect boards and find bad joints, misplaced components, and in some cases, wrong components.

4)PCBA Test

Electronic PCBA products must be tested before shipping to the customer. There are several ways to test them.

5)Quality Inspection

In order to ensure the smooth operation of the PCBA manufacturing process, it is necessary to conduct quality inspections on the output products, which is to get rid of the possible faults that may detect. If find any faults, the ideal place is in the optical inspection stage, as this usually happens immediately after the soldering stage, which means that process defects can be quickly detected and repaired before a great number of circuit boards with the same problems are manufactured.