In the consultation of many customers, there are many questions about PCB Array Prototype. So, what are the benefits of PCB Array Prototype?

The Benefits of PCB Array Prototype

1. In order to improve the pass rate of electronic products, it is necessary to have a predictable guarantee for the quality of its core component – PCB, so it is necessary to carry out a small amount of production through PCB prototype first to test the performance of products, which can not only improve production Efficiency but also reduce production costs.

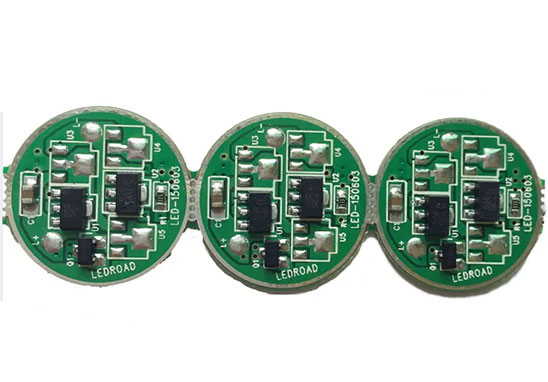

2. PCB Array Prototype is an effective measure to reduce production costs. The PCB Assembly process will be much less for the entire PCBA process. Whether the whole assembly is 20 pieces or 10 pieces, it maximizes the use of production resources and improves the efficiency of production.

3. PCB Array Prototype is of great benefit to the manufacturer’s front-end engineering. They can better participate in the production of customers’ products and better understand the production and process difficulties of customers’ products; It is of great benefit to the subsequent quality control of product production. Such early participation helps to control production risks and improve customer satisfaction.

4. It can minimize the quality problems that may be encountered in mass production. After all, ensuring a good reputation is crucial for a manufacturer.

Grande Advantages of PCB Prototype

Mass production 2 to 14 layers, 14-22 layers can be produced by prototype.

Minimum Trace Width/Spacing: 3mil/3mil BGA spacing: 0.20MM

Minimum Aperture of Finished Product: 0.1mm Size: 610mmX1200mm

Ink: Japan Tamura, Taiyo, Futoken;

FR4: Shengyi, Kingboard, Haigang, Hongren, Guoji, Hazens, South Asia,

(Shengyi S1130/S1141/S1170), Tg130℃/ Tg170℃ Tg180℃ and other high TG plates)

High Frequency Board: Rogers (Rogers), Taconic, ARLLON;

Surface Technology: Spray tin, lead-free spray tin, immersion gold, full board gold plating, plug gold plating, full board thick gold, chemical immersion tin (silver), anti-oxidation (OSP) blue glue, carbon oil

Advantages Grande Circuit Board Assembly

1)Strength Guarantee

2)Quality Assurance With High Cost Performance

3)Rich Electronic Products SMT Soldering Experience With Stable Delivery

4)Strong Maintenance Ability & Reliable After-Sales Service