What’s the minimum required length of SMT materials tape In PCBA Prototype? Generally, the material for SMT Assembly Prototype and trial production is relatively short, and it is not easy to load the materials. It is necessary to set a standard. So how long is the material tape length, and can the SMT factory accept it?

Minimum Required Length Requirement of Materials Tape For PCBA Prototype

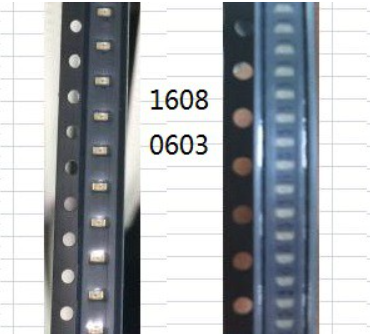

In the SMT production process, the materials are mainly packaged in trays and tapes. This packaging method is convenient for the placement machine to pick up the material and improve the production efficiency. Among them, the tape is installed on the feeder, and then the pick and place machine takes the material. In the process of PCBA prototype, due to the relatively small number, the length of the material tape will affect the pick-up of the placement machine. In the actual SMT Assembly process, the shortest length of the tape is 10cm, but this is not the industry standard. The acceptable length of each factory is different, which depends on the quality of the placement machine and feeder, as well as the material If possible, try to ask customers to provide more materials to ensure safe production.

Grande SMT Assembly Prototype Trial Production: Due to different types of feeders, too short materials tape is time-consuming and labor-intensive, the key is to explain to the customer in advance, let the customer decide whether he/she is willing to buy a few more materials, or is willing to extend the Assembly time and pay more assembly fee; BTW, the shortest material tape for PCBA Prototype Standard set by Grande is 10cm around.

The packaged material only needs to be stuck by the feeder, generally a 10cm tape is enough. However, considering the possibility of defects such as throwing materials, it is also okay to prepare a little more. After all, the 0603 materials are not too expensive.

SMT Assembly Capability

1. Maximum Board: 310mm*410mm(SMT);

2. Maximum Board Thickness: 3mm;

3. Minimum Board Thickness: 0.5mm;

4. Minimum Chip Components: 0201 package or components above 0.6mm*0.3mm;

5. Maximum Weight of Mounted Components: 150 grams;

6. Maximum Component Height: 25mm;

7. Maximum Component size: 150mm*150mm;

8. Minimum Pin Spacing: 0.3mm;

9. Minimum Spherical Component (BGA) Spacing: 0.3mm;

10. Minimum Spherical Component (BGA) Ball Diameter: 0.3mm;

11. Maximum Components Placement Accuracy (100QFP): 25um@IPC;

12. SMD Capacity: 3-4 million points/day.

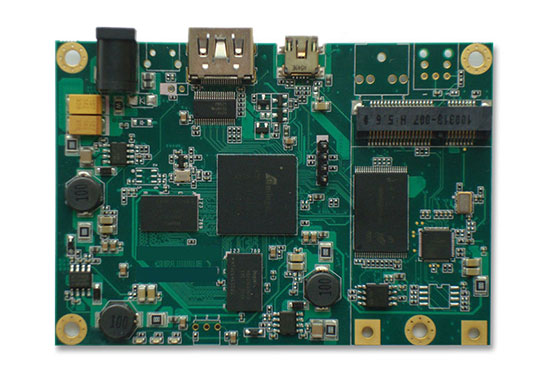

Why Choose Grande To Do PCB Assembly?

1)Strength Guarantee

▪ SMT factory: With imported SMT machines and multiple optical inspection equipment, which is able to produce 4 million points per day. Each process is equipped with QC personnel who will keep an eye on product quality.

▪ DIP production line: Two wave soldering machines and more than 10 employees who have worked for over three years. That’ s to say, these workers are highly skilled and can weld various SMT & DIP components.

2)Quality Assurance With High Cost Performance

▪ High-end equipment can paste precision special-shaped parts, BGA, QFN, 0201 package. It can also be soldered prototype pcba via SMT machine and placing bulk materials by hand.

▪ Both samples, small and large batches can be produced. And there is no SMT Machine starting cost.

3)Rich Electronic Products SMT Soldering Experience With Stable Delivery

▪ Accumulated services to thousands of electronics companies, involving SMT soldering services for various types of automotive equipment and industrial control motherboards. Furthermore, PCBA Products are often exported to Europe and the United States, and the quality is able to be affirmed by new and regular customers.

4)Strong Maintenance Ability & Reliable After-Sales Service

▪ The maintenance engineers have sophisticated experience so that those defective boards caused by all kinds of smt soldering can be repaired. Meanwhile, ensuring the connectivity rate of each circuit board also make sense.

▪Order problems feedback will get response, solution and solved as soon as possible.