In order to avoid the problem of BGA solder joints on the top side of the circuit board, the temperature of SMT Factories should not exceed 150°C during the tin/lead wave soldering process, and also should not exceed 190°C for lead-free alloy wave soldering.

Influence of SMT Wave Soldering On PCBA Top Side BGA

A common assembly sequence for printed board hybrid technology in SMT factories is to first reflow the surface mount package on the top side of the board, and then wave solder the through-hole package (inserted from the front). For double-sided boards, bottom side surface mount components are usually mounted before top side components, and they are held in place by reflow soldering or dispensing. The bottom side components should be separated from the wave crest by the wave solder carrier, if not glued in place. Surface mount components that have been reflowed on the top of the board are also heated during the wave soldering process. When the temperature rises close to the liquidus point of the solder alloy, this heating can cause the solder joints of these components to melt. Therefore, care should be taken to prevent the solder joint temperature of these components from reaching the liquidus temperature during PCBA SMT Assembly.

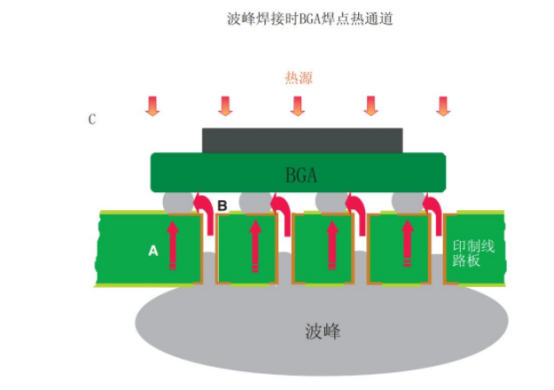

Effects of top side reflow BGA solder joints require special attention because their solder joints are under stress during the wave soldering process. If these solder joints reach liquidus temperature (183°C for eutectic tin/lead solder composition; 217°C for SAC alloy), then there is dewetting or dewetting of the solder joints due to the thermomechanical strain caused by the heating process. Potential risk of PCB/package substrate detachment. Due to the solder is extremely soft, even at temperatures close to the liquidus, there is a risk of cold soldering, dewetting, or deformation of the solder balls when the temperature does not reach the solidus. Figure 6-24 depicts solder ball deformation and dewetting in a BGA components on the top side of the motherboard. During wave soldering, BGA solder joints reach a peak temperature of 180°C. BGA solder joints are more prone to these defects than leaded surface mount solder joints because they lack strain relief.

In order to avoid the problem of BGA solder joints on the top of the circuit board, the temperature of SMT manufacturers should not exceed 150°C during the tin/lead wave soldering process, and should not exceed 190°C for lead-free alloy wave soldering. This is lower than the maximum temperature allowed for fine pitch leaded components such as plastic QFPs. The figure is an example of the acceptable temperature profile of a solder joint on a circuit board soldered by a hybrid technique during a wave soldering process. SMT determines the various ways to keep the temperature below 150°C (190°C for lead-free), it is best to first identify the various ways in which the BGA solder joints are heated in the wave soldering process. The figure shows three paths, path A is through the circuit board heat conduction from the back to the front. Path B conducts through the via walls, along the conductors connecting the vias to the BGA pads. Path C is the convection and radiation from the pre-heater located above the wave soldering equipment.

Advantages Grande Circuit Board Assembly

1)Strength Guarantee

▪ SMT factory: With imported SMT machines and multiple optical inspection equipment, which is able to produce 4 million points per day. Each process is equipped with QC personnel who will keep an eye on product quality.

▪ DIP production line: Two wave soldering machines and more than 10 employees who have worked for over three years. That’ s to say, these workers are highly skilled and can weld various SMT & DIP components.

2)Quality Assurance With High Cost Performance

▪ High-end equipment can paste precision special-shaped parts, BGA, QFN, 0201 package. It can also be soldered prototype pcba via SMT machine and placing bulk materials by hand.

▪ Both samples, small and large batches can be produced. And there is no SMT Machine starting cost.

3)Rich Electronic Products SMT Soldering Experience With Stable Delivery

▪ Accumulated services to thousands of electronics companies, involving SMT soldering services for various types of automotive equipment and industrial control motherboards. Furthermore, PCBA Products are often exported to Europe and the United States, and the quality is able to be affirmed by new and regular customers.

4)Strong Maintenance Ability & Reliable After-Sales Service

▪ The maintenance engineers have sophisticated experience so that those defective boards caused by all kinds of smt soldering can be repaired. Meanwhile, ensuring the connectivity rate of each circuit board also make sense.

▪Order problems feedback will get response, solution and solved as soon as possible.