SMD Resistors & Capacitors & SMD Inductors are widely used in consumer electronics, small equipment products, and automotive electronic products. With the demand for thinning and miniaturization of electronic products, the dimensional precision of SMD Resistors & Capacitors are getting higher and higher. In 2018, the smallest chip resistor size is precisely 01005, and the commonly used smd resistors, smd inductors and smd capacitors are difficult to distinguish in appearance. Then how to distinguish SMD resistors, SMD capacitors and SMD inductors in SMT Assembly?

Distinguishing Method of SMD Resistor & SMD Capacitor

1. Look at the color – All SMD capacitors do not have silk screen printing. Its color is mostly blue-gray.

2. Look at the mark – The symbol of the SMD capacitor in the circuit is “C”, and the symbol of the SMD resistor is “R”.

3. Look at the silk screen – The abnormality with silk screen is usually resistor.

Distinguishing Method of SMD Capacitor & SMD Inductor

1. Look at the color – Usually only the tantalum capacitor is black, and the others are not black at all. The SMD inductors are basically black.

2. Look at the model code – SMD inductors begin with L, and SMD capacitors begin with C. Judging from the shape of the rounded start, it should be an inductor.

3. Look at the external layout – you can find similar components or unassemble the components to see the external layout, and those with coil layouts are SMD inductors.

Distinguishing Method of SMT Resistor & SMD Inductor

1. According to the shape – the shape of the inductor has a polygonal shape, while the resistor is basically a rectangle. Especially when it is round, it is usually regarded as an inductance.

2. Measure the resistance value – The resistance value of the inductor is relatively small, and the resistance value of the resistor is relatively large.

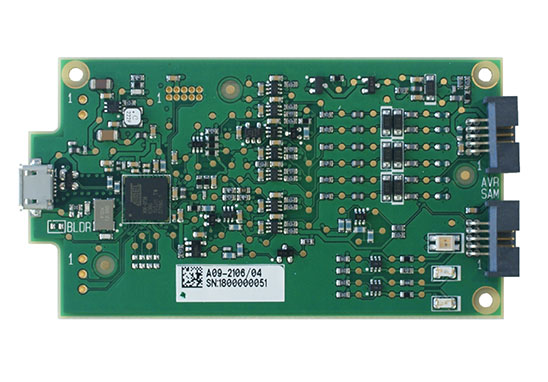

Advantages of car key circuit board assembly

1)Strength Guarantee

▪ SMT factory: With imported SMT machines and multiple optical inspection equipment, which is able to produce 4 million points per day. Each process is equipped with QC personnel who will keep an eye on product quality.

▪ DIP production line: Two wave soldering machines and more than 10 employees who have worked for over three years. That’ s to say, these workers are highly skilled and can weld various SMT & DIP components.

2)Quality Assurance With High Cost Performance

▪ High-end equipment can paste precision special-shaped parts, BGA, QFN, 0201 package. It can also be soldered prototype pcba via SMT machine and placing bulk materials by hand.

▪ Both samples, small and large batches can be produced. And there is no SMT Machine starting cost.

3)Rich Electronic Products SMT Soldering Experience With Stable Delivery

▪ Accumulated services to thousands of electronics companies, involving SMT soldering services for various types of automotive equipment and industrial control motherboards. Furthermore, PCBA products are often exported to Europe and the United States, and the quality is able to be affirmed by new and regular customers.

4)Strong Maintenance Ability & Reliable After-Sales Service

▪ The maintenance engineers have sophisticated experience so that those defective boards caused by all kinds of smt soldering can be repaired. Meanwhile, ensuring the connectivity rate of each circuit board also make sense.

▪Order problems feedback will get response, solution and solved as soon as possible.