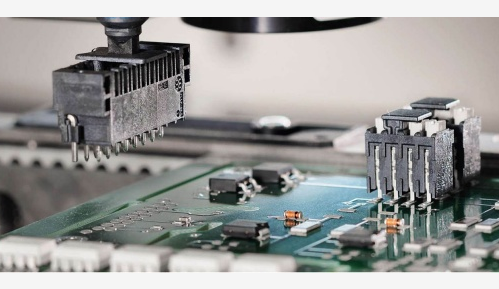

After PCB Assembly is completed, the circuit board needs to be debugged to verify whether the function is normal; Then how should we debug the assembled printed circuit board?

Steps & Methods of PCBA Debugging

1. Board Surface Observation & Resistance Check

First, observe whether there are any problems on the board, such as cracks, short circuits, open circuits, etc. If necessary, check whether the resistance between the power supply and the ground wire is large enough.

2. Install The Modules

Independent modules, when you are not sure whether they are working properly, it is best to install them one by one, so as to easily determine the scope of the PCB failure.

3. Detect The Output Voltage of The Power Supply

Generally speaking, you can install the power supply first, and then power on to check whether the output voltage of the power supply is normal. When supplying power, consider to use an adjustable regulated power supply with current limiting function.

4. Preset Overcurrent Protection Current

First of all, preset the overcurrent protection current, and then slowly increase the voltage value of the regulated power supply to monitor the input current, input voltage, and output voltage. If there is no overcurrent protection and other problems during the upward adjustment process, and the output voltage has reached normal, it means that the power supply is normal.

5. Install Other Modules & Power-On Test

Install other modules step by step, and power up and test each time the module is installed to avoid overcurrent and module burnout due to design errors or component installation errors.

Grande PCBA Advantages

1. Highly Professional: Focuse on assembling samples, small and medium batches, and promises to deliver goods within 3-5 working days after the materials are confirmed.

2. Professional Equipment: Advanced equipment tailored for sample and small and medium batch production, which can be attached to 0201, BGA pitch 0.3MM, QFN, CSP, CON and other components.

3. Professional Technology: 100% sophisticated technicians have more than 5 years of work experience, and 85% of frontline operators have more than 3 years of work experience.

4. Implement the 5S and 6σ concepts in its daily operations, and has at least 7 times inspection from incoming materials to shipments.

5. Promise that the soldering pass rate is over 99%. If the customer finds soldering defects, Grande will repair it for free.