Many newcomers who are just entering the industry have doubts about PCB Color, and do not know which color PCB is of high quality. In fact, PCB mainly provides the interconnection between components, and its color has no direct relationship with performance and quality, and the difference in color does not affect the electrical properties.

The Relationship Between PCB Quality & PCB Color

The raw material of PCB is seen everywhere in our daily life, that is, glass fiber and resin. The glass fiber and resin are combined and hardened to become a heat-insulating, insulating, and not easy to bend board, which is the PCB substrate. Of course, PCB substrates made of glass fiber and resin alone cannot conduct signals. Therefore, on the PCB substrate, the manufacturer will cover a layer of copper on the surface, so the PCB substrate can also be called a copper-clad substrate.

There is a situation that makes people mistakenly think that the quality of the PCB board is related to the quality of the PCB color: individual PCB design uses black, which is likely to cause color difference during the PCB washing process; if the raw materials and production processes used by the PCB factory are slightly different, The PCB defect rate will increase due to chromatic aberration, which directly leads to an increase in production costs. Since the circuit traces of the black PCB are difficult to identify, it will increase the difficulty of repair and debugging during the R&D and after-sales stages. Generally, brands without strong RD (R&D) designers and powerful maintenance teams will not easily use black PCBs. . Based on the above reasons, when major manufacturers choose PCB designs for their products, most of them use red PCBs, green PCBs or blue PCBs. Black PCBs are rarely seen.

In short, the performance of the PCB board is determined by factors such as the material used (high Q value), wiring design and several layers of the board; the quality of the PCB board has nothing to do with the color of the PCB.

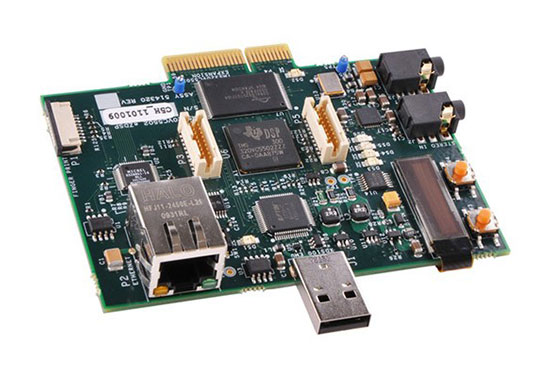

PCB Manufacturing Capability

The energy production is from 2 to 14 layers, and the 14-22 layers can be sampled and produced.

Minimum line width/spacing: 3mil/3mil BGA spacing: 0.20MM

The smallest aperture of the finished product: 0.1mm Size: 610mmX1200mm

Ink: Tamura, Taiyo, Fudokken from Japan;

FR4: Shengyi, Kingboard, Haigang, Hongren, Guoji, Hazheng, Nanya,

(Shengyi S1130/S1141/S1170), Tg130℃/ Tg170℃ Tg180℃ Contour TG sheet)

High frequency board: Rogers (Rogers), Taconic, ARLLON;

Surface technology: tin spray, lead-free tin spray, immersion gold, full board gold plating, plug gold plating, full board thick gold, chemical tin (silver), anti-oxidation (OSP) blue glue, carbon oil

PCBA Prototype Flow

1. Customer orders

Customers place orders according to their actual needs, PCBA processing plants, and put forward specific requirements. The processing plant will evaluate its own capabilities to see if it can complete the order. If the manufacturer determines that it can complete the order within the expected time, then the two parties will negotiate to determine the production details.

2. Customers provide production materials

After the customer decides to place an order, he provides a series of documents and checklists to the PCBA processing plant, such as PCB electronic files, coordinate files, and BOM lists required for production, which are all required.

3. Procurement of raw materials

PCBA processing plants purchase relevant raw materials from designated suppliers according to the documents provided by customers.

4. Incoming Material Inspection

Before PCBA processing, all raw materials to be used are subjected to strict quality inspection to ensure that they are qualified and put into production.

5. PCBA production

During PCBA processing, in order to ensure the quality of production, whether it is patch or solder production, manufacturers need to strictly control the furnace temperature.

6. PCBA test

The PCBA processing plant conducts strict product testing, and the PCB boards that pass the test are delivered to the customer.